Article

- Title: Digital Twins (DT), 5G connectivity, and future robotics applications in the maritime industry

- Author: Lim Zhi Qing

- Date: 29 September, 2023

- Reading time: 5-7 minutes

Summary

In this article, Lim Zhi Qing examines the merits of deploying emerging technologies, such as digital twins and robotics, with 5G connectivity in the maritime industry. The author highlights present applications and future possibilities.

Digital Twins (DT), 5G connectivity, and future robotics applications in the maritime industry

Lim Zhi Qing

Centre Manager at Centre for 5G Digital Building Technology (C5GDBT)

Department of the Built Environment, National University of Singapore

Disclaimer: The views and opinions expressed in this article are those of the author and do not necessarily reflect the views or positions of the university.

1. Overview

At C5GDBT, our vision is to position ourselves as a pioneering hub in the field of digital building technology, achieved through the pursuit of high-impact research, comprehensive educational initiatives, and the adoption of industry-leading practices. By harnessing the transformative potential of 5G technology, our team has not only created a proprietary Digital Twin (DT) model that seamlessly integrates robotics and advanced smart sensors but has also significantly elevated our competencies in the domain of smart facilities management. Since our establishment, the Centre received esteemed visitors and hosted training workshops for more than 1,200 professionals and students.

Introduction video of C5GDBT:

2. Introduction

Over the years, as technology has advanced and smart technologies like artificial intelligence (AI), machine learning (ML), and automation have gained prominence in various industries, including the maritime sector, innovative maritime concepts such as 'smart ships,' unmanned and autonomous vessels, and 'smart harbours' are becoming increasingly prevalent.The government aims to ensure nationwide 5G network coverage by mid-2025, including the maritime industry across key anchorages, fairways, terminals, and boarding areas. 5G represents a significant leap forward from 4G, providing notable advantages like higher data transfer speeds, minimal data transmission delays (latency), and more extensive data capacity (bandwidth). These advancements hold great promise for the maritime industry. In this article, we will explore the application of 5G for DT and robotics.

With 5G's enhanced speed, maritime professionals can create and maintain highly detailed and dynamic DTs of ships, ports, and maritime assets. These DTs can be updated almost in real-time, enabling precise modelling and analysis of intricate maritime scenarios. Furthermore, in the realm of robotics, 5G empowers robots on ships and within port facilities to process and respond to data swiftly. This translates to quicker decision-making, improved situational awareness, and, ultimately, enhanced safety and operational efficiency.

3. What is Digital Twin?

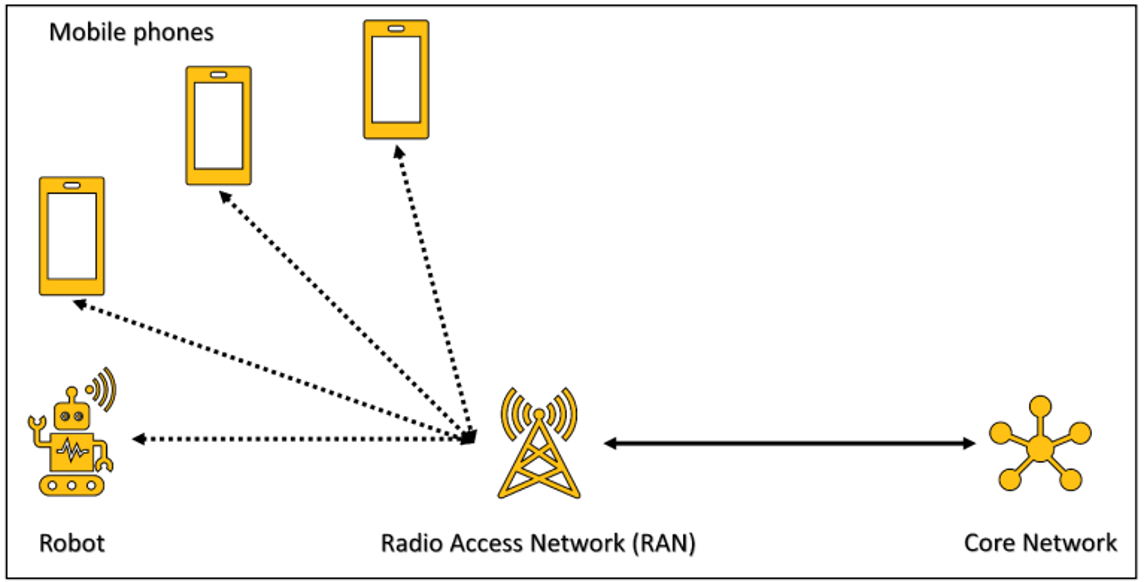

DT is essentially a virtual replica of physical assets and a dynamic model that can simulate and optimise various scenarios and outcomes. DT contains vast amounts of real-time information and big data that exceed the capacity of 4G networks. However, with the advent of 5G and the potential of upcoming 6G network technology, the deployment of real-time DT has become feasible, thanks to the concept of network slicing. Network slicing (see Figure 3) is a fundamental concept in 5G technology. It allows for the allocation of dedicated virtual network segments for specific applications or services. This ensures that the required network resources are available to support the continuous operation of Digital Twins without interference from other data traffic. It guarantees reliable and predictable connectivity, which is essential for critical maritime operations.

4. What are the benefits of DT in the Maritime Industry?

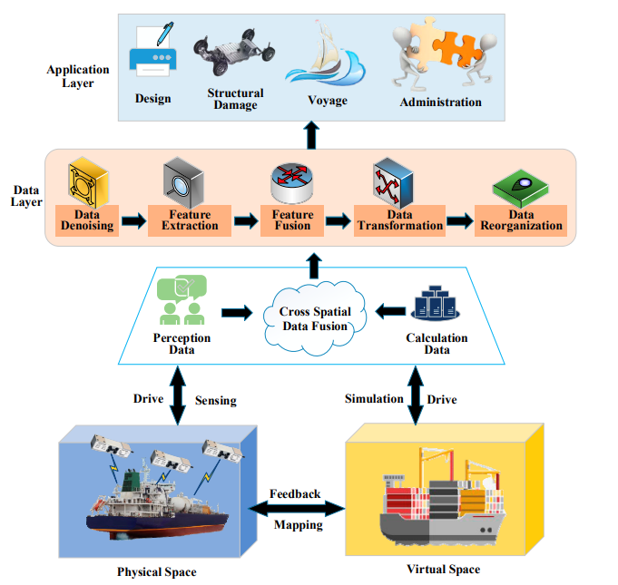

Figure 4 illustrates the system architecture for the application of DT technology within the maritime industry, demonstrating the bidirectional flow of data between the physical and virtual realms. Employing DT offers numerous advantages to the industry, including real-time monitoring and analysis, predictive maintenance, resource optimisation, heightened safety, and versatile training capabilities, as detailed in the subsequent discussion.

The bidirectional data exchange showcased in Figure 4 enables real-time monitoring and analysis of maritime assets and operations. Data from physical assets, such as ships, sensors, and equipment, is continuously and instantaneously transmitted to the virtual DT through the common data environment (CDE). This real-time data flow allows maritime professionals to gain immediate insights into asset status and performance. For instance, they can monitor engine parameters, fuel consumption, cargo conditions, and environmental factors as they occur. Such real-time capabilities are invaluable for making swift, informed decisions.

Another key benefit of DT is its ability to conduct accurate predictive maintenance. By continuously comparing real-time data from physical assets to the virtual model, anomalies and potential issues can be detected early. Maintenance crews receive alerts and notifications, enabling them to address problems before they lead to costly breakdowns or delays. This proactive approach not only saves time and money but also enhances overall safety.

Figure 4 also illustrates how data exchange optimises resource management in the maritime industry. For example, cargo loading and unloading operations in a smart port can be fine-tuned based on real-time data, reducing idle times and improving efficiency. In vessel navigation, the DT assists in route planning and fuel optimisation by continuously updating data from ship sensors and environmental conditions.

Bidirectional data exchange ensures safety-critical information is readily available in both the physical and virtual domains, enhancing safety in various ways. For instance, in adverse weather conditions or equipment failures, the DT can suggest alternative routes or actions to avoid potential risks. Additionally, constant monitoring of safety parameters leads to faster responses to emergencies, such as oil spills or onboard fires.

Finally, the DT serves as a platform for training scenarios and simulations, allowing maritime professionals to practise emergency responses, navigation in challenging conditions, and other critical tasks in a safe and controlled virtual environment.

5. Robotics Application in the Maritime Industry

The integration of robotics into the maritime industry is no longer a groundbreaking concept. For instance, in Singapore, automated guided vehicles (AGVs) currently play a pivotal role in automating yard and wharf operations at Tuas Port due to their adaptability and agility in picking up and transporting containers. DT serves as a platform which hosts various Internet of Things (IoT) sensors, 4K video camera feeds for video analytics, facial recognition (FR) capabilities, AI and ML. Coupled with the advantages of 5G network, this advanced technology can potentially allow robots such as AGVs to carry out autonomous tasks. Moreover, the DT could issue instructions to the AGVs as needed for task completion while concurrently overseeing extensive fleets of robots within a unified DT system, eliminating the necessity of managing various robotics systems for distinct robot fleets.